Alex Matveev (LinkedIn), developer of PASS/Start-Prof software, which is used in 95% of Russian companies since 1965.

Please follow, like and share PASS: Youtube Channel, Facebook, LinkedIn, Twitter Read about START-PROF pipe stress analysis software

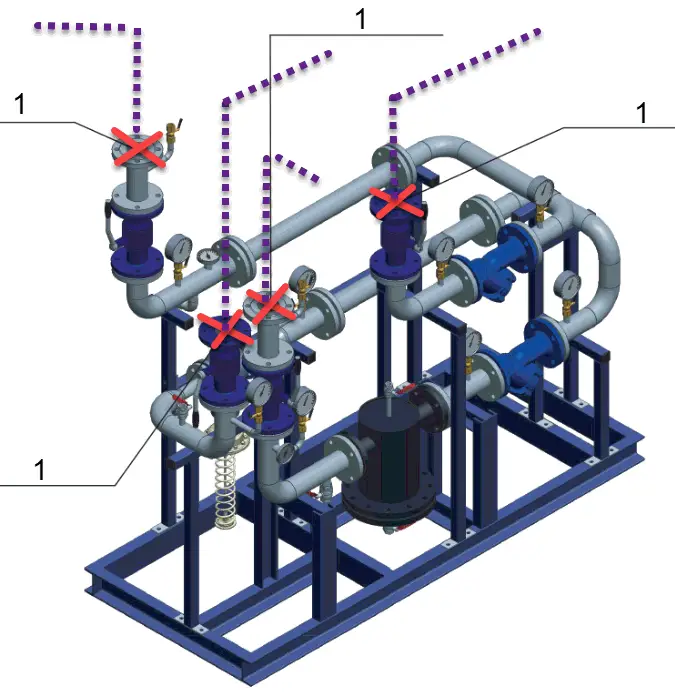

The idea of modular design is following. The complex piping system is divided into several modules that is mounted on a frame structure. Modules can be transported to the site and joined to each other into entire piping system. One of the modules is shown on the picture below. At the points “1” external piping or other module piping are connected.

Stress analysis of separate module for temperature expansion and other loads acting on a whole system is impossible. Only whole system can be analyzed. Exception: when anchors are added at all connection points between modules. But in this case design for temperature expansion will become extremely hard.

The practical solution for this problem is following:

Option 1. Module manufacturer perform it’s stress analysis with using of several, the most unfavourable variants of external piping design. Stress analysis should be successful for all variants. After that manufacturer pass the START-PROF module piping model to customer. Customer adds the module model to own piping model and perform analysis of the whole system.

Option 2. Customer adds anchors or hinged anchors at the points, where his piping model is connected to module. Performs stress analysis and optimize design. After that he pass the START-PROF piping model to the module manufacturer, who join this model to the module piping model and preforms whole system stress analysis.

here’s also Option 3. Too complex and hard. Module manufacturer offers 6 stifnesses (Kx,Ky,Kz, KRx, KRy, KRz) for each connection point and temperature expansions (point movements). Also stifness matrix 6×6 can be offered. Customer adds these stifnesses and add support movements. But after analysis he must pass new movements of connection points back to manufacturer.

Also piping systems usually is nonlinear. Some restraints may switch off, friction behavior may be different, therefore manufacturer should perform new analysis and generate new stifnesses and new movements. The disegn process will become iterative. If piping system has several operation modes with various temperatures, this work becomes almost impossible. Much more easy to offer the whole piping model to counterpart. This option can only be used if manufacturer wants to keep the design secret, but don’t want to use Option 2 for some reasons.

Transportation Stage

Transportation stage should be calculated for both options described above. The system should have transportation configuration (locked springs, added temporary supports, detached flanges etc.) and analyzed for inertial loads and vehicle body deformations during transportation. Added ice, show, wind, impact, and other possible loads.

EDS ASIA SDN BHD

Address: No 11-A, Jalan SS2/66, 46200 Petaling Jaya, Selangor,

MALAYSIA.

Tel: +603-7876 9911

email pipestress@eds-asia.com atau sales@eds-asia.com

atau bisa ke WA 08117603471 ke email iwanagung1971@gmail.com

1D8A6B14B5

ReplyDeleteTakipçi Satın Al

En İyi Güneş Kremi

Beğeni Hilesi

En İyi Kore Dizileri

Film Önerisi

En İyi Ücretsiz Oyunlar

Manga Oku TR

Site Kurma

Takipçi Satın Al